Construction joint systems

Edging systems for joint band installation, type AKB | AKB1 | AKB2 | AKB32 | AKB3

The MSL systems for joint bands meet DIN V 18197: 2005-10 requirements.

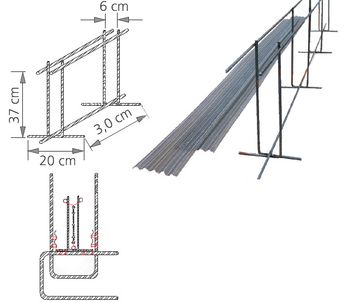

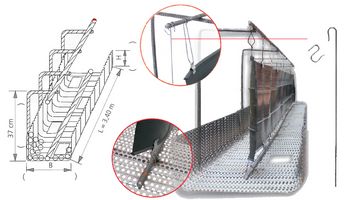

Type AKB - Edging with joint band bracket

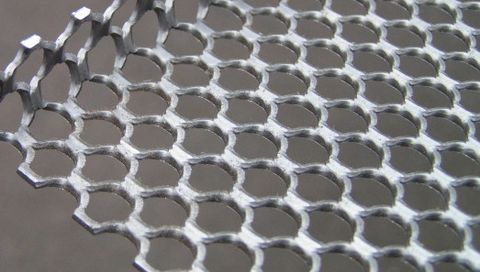

The system consists of U-shaped folded edge corrugated profile perforated sheet metal elements. Constructional steel rods are welded on top and bottom to secure the joint band.

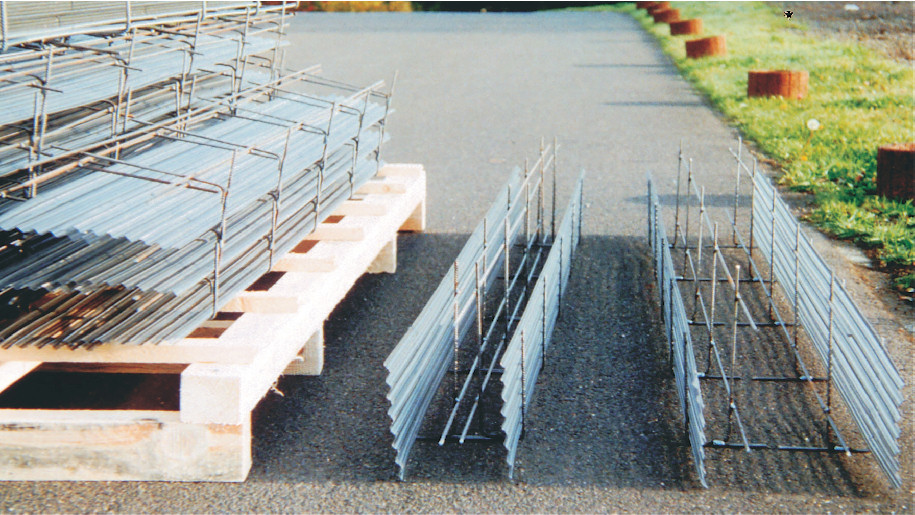

Element length is 3.4 m. Element width, edging and bracket height to client specifications.

System specifications:

In installing the joint bands make sure the fastening and support elements satisfy the DIN V 18197: 2005-10 requirement for a minimum gap of 2 cm to the joint band. Fastening point intervals shouldn't exceed 25 cm. Interior joint bands in horizontal and slightly tilted building components such as floors and ceilings are to be laid V-shaped for ventilation during concreting. To fasten the joint bands to the MSL products we recommend using MSL fastening hooks.

Benefit: simplified installation and time savings.

Type AKB1 - Edging with joint band bracket

Design as type AKB but with 4 apertures for vibrating.

Type AKB2 - Two-part edging

Element length 3.0 m, open base. Edge width, height and element height to client specifications.

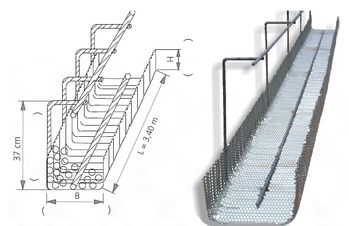

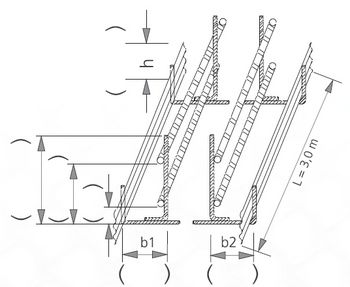

Type AKB3 - Joint band guide element with 2 loose metal sheets on edge

The 3.0 m-long joint band guide element consists of 4 joint band brackets permanently mutually connected by 3 longitudinal steel rods. The loose corrugated profile perforated metal sheets are fastened to the vertical reinforcement. The joint band is inserted in the bracket/s on site and secured top and bottom to the longitudinal steel rods.